STELLENANGEBOTE

Ihre Vorteile

Diese Animation zeigt Ihnen, wie wir als ELCEE Ihre Projekte für technische Komponenten und Baugruppen aus Metall abwickeln. Ich hoffe, dies hilft Ihnen zu verstehen, wie wir Sie bei der Umsetzung Ihrer Projekte unterstützen können. Unsere ELCEE-Kollegen vor Ort sind gerne für Sie da.

Mit freundlichen Grüßen,

Michael R. Bach

Geschäftsführer Elcee G.m.b.H

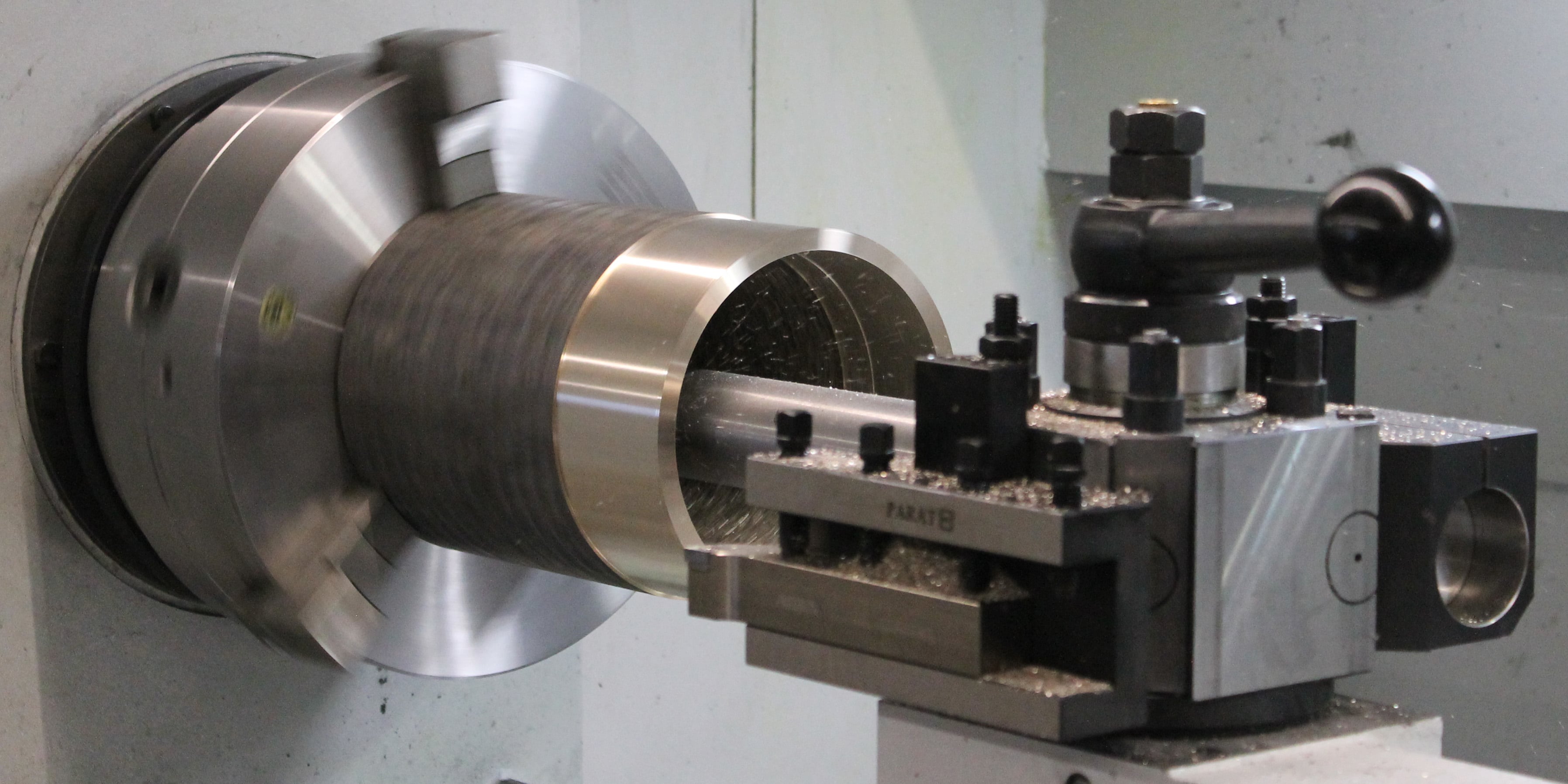

Unsere Fähigkeiten

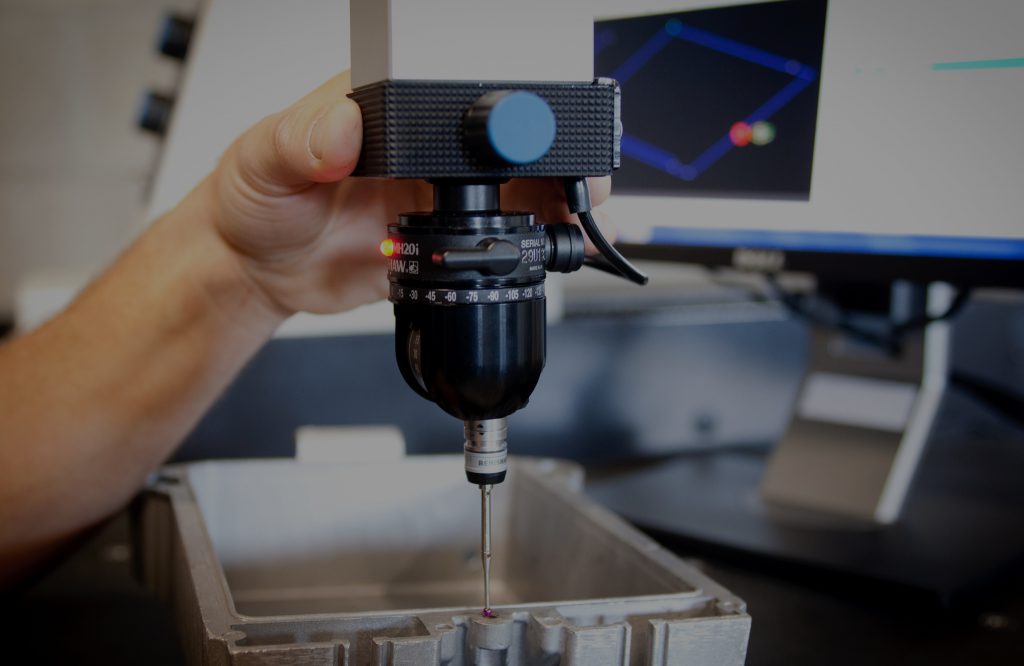

Unsere Qualitäten

Know-how

Dank unserer 100-jährigen Erfahrung sind wir ein echter Wissenspartner

Cost Engineering

Umwandlung von Schweißbaugruppen in kostengünstige Guss- und Schmiedeteile

Qualität

Versand von ausschließlich hochwertigen und geprüften Produkten

Produktion

Produktionsnetzwerk, Portfolio mit globalen Produktionsstandorten

Lokalmatador

ELCEE ist Ihr lokaler Lieferant in einer globalen Wirtschaft

Supply chain management

Organisation der Lieferkette von der Herstellung bis zu Ihrer Produktionslinie